Robotic Applications

We carry your production processes to the future with advanced technology robotic systems Daha fazla verimlilik, esneklik ve kalite için anahtar teslim çözümler sunuyoruz.

Arc Welding

Arc welding applications involve joining metal parts through electric arc welding under a protective gas atmosphere. In this system, robotic arms follow programmed welding paths with millimetric precision, ensuring consistent quality in every weld. Robotaryum integrates MIG/MAG and TIG welding technologies with industrial robots, delivering high-strength joints across a wide range from automotive to heavy industry.

Learn MoreRobotic Cutting

Industrial cutting processes encompass precise shaping of metal, composite, and plastic materials using spindle milling and plasma technologies. Robotic cutting systems directly process CAD/CAM data to cut complex geometries with 0.1mm tolerance. Robotaryum equips 6-axis robots with specialized cutting attachments, automating all types of cutting operations from aerospace components to machine parts.

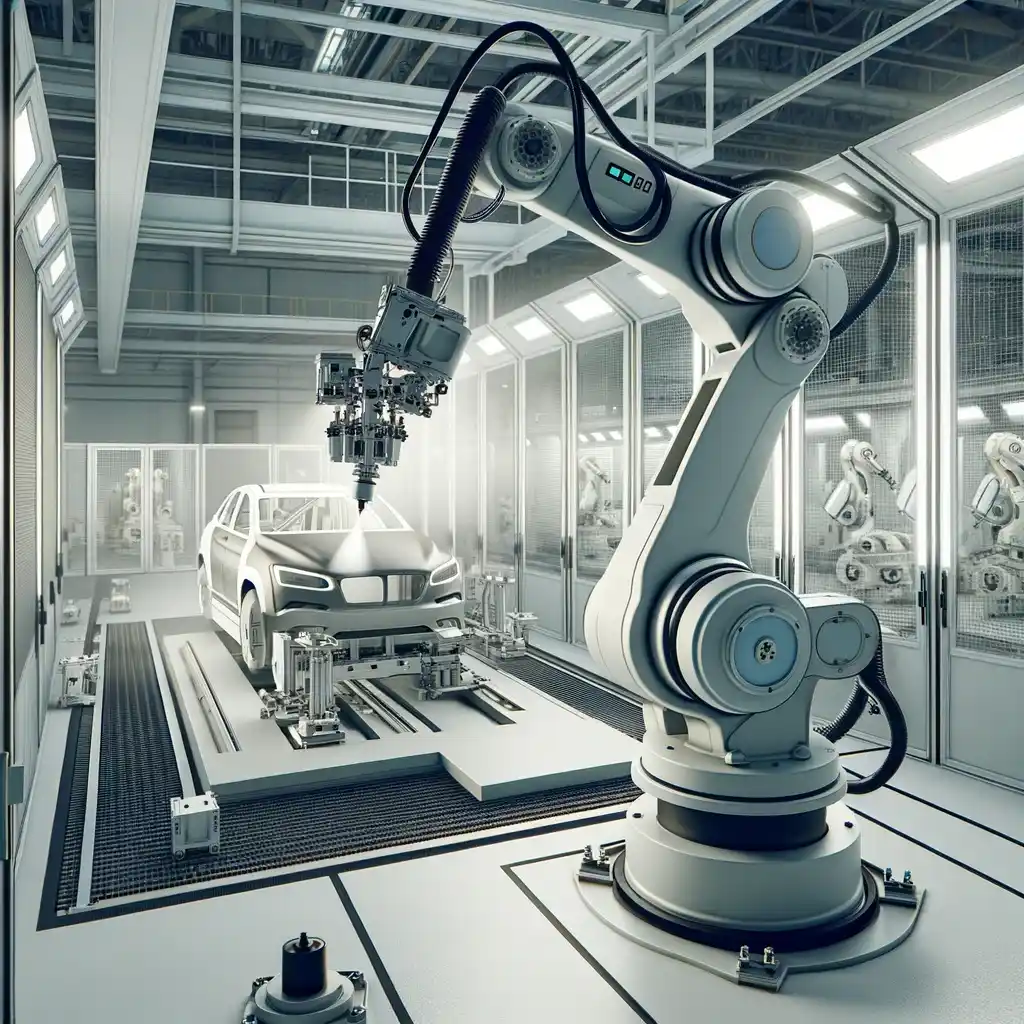

Learn MorePainting and Spraying

Industrial painting is a critical process for protecting products against corrosion and providing aesthetic appearance. Paint robots equipped with electrostatic spray technology and precise flow control ensure uniform coating thickness even on complex surfaces. Robotaryum standardizes production quality by safely applying solvent-based and water-based paints with Fanuc's Ex-proof certified paint robots.

Learn MorePalletizing

Palletizing is the process of stacking products from the production line onto pallets in a specific order. Robotic palletizing systems, equipped with vision processing and force sensors, recognize products of different sizes and weights and arrange them according to optimal placement plans. Robotaryum maximizes pallet fill rate through intelligent software algorithms while applying safe gripping and placement techniques that minimize product damage.

Learn MorePress Feeding

Press feeding automation involves placing raw material in precise positions in press dies and removing processed parts in sheet metal forming processes. Servo motor-controlled robots work in full synchronization with press machines, performing transfers with millisecond precision. Robotaryum establishes systems equipped with safety laser scanners and force-torque sensors, ensuring operator safety while optimizing cycle times.

Learn MoreSpot Welding

Spot welding is the process of joining two or more metal sheets through electrical resistance principle. Robots equipped with servo welding guns apply precise pressure and current to programmed welding points, creating metallurgical bonds. Robotaryum provides automation solutions particularly in automotive body production, performing 3000-5000 welding points on a vehicle body with high speed and consistency.

Learn More

Additional

Services

Ek hizmetlerimiz, robotik uygulamalarınızı tamamlayan ve iş süreçlerinizi optimize eden kapsamlı çözümlerdir.