Needle Flow Control Valves - NVH101S

SKU:

NVH101S

In Stock (15 items)

198 views

€0,00

VAT Included

Product Summary

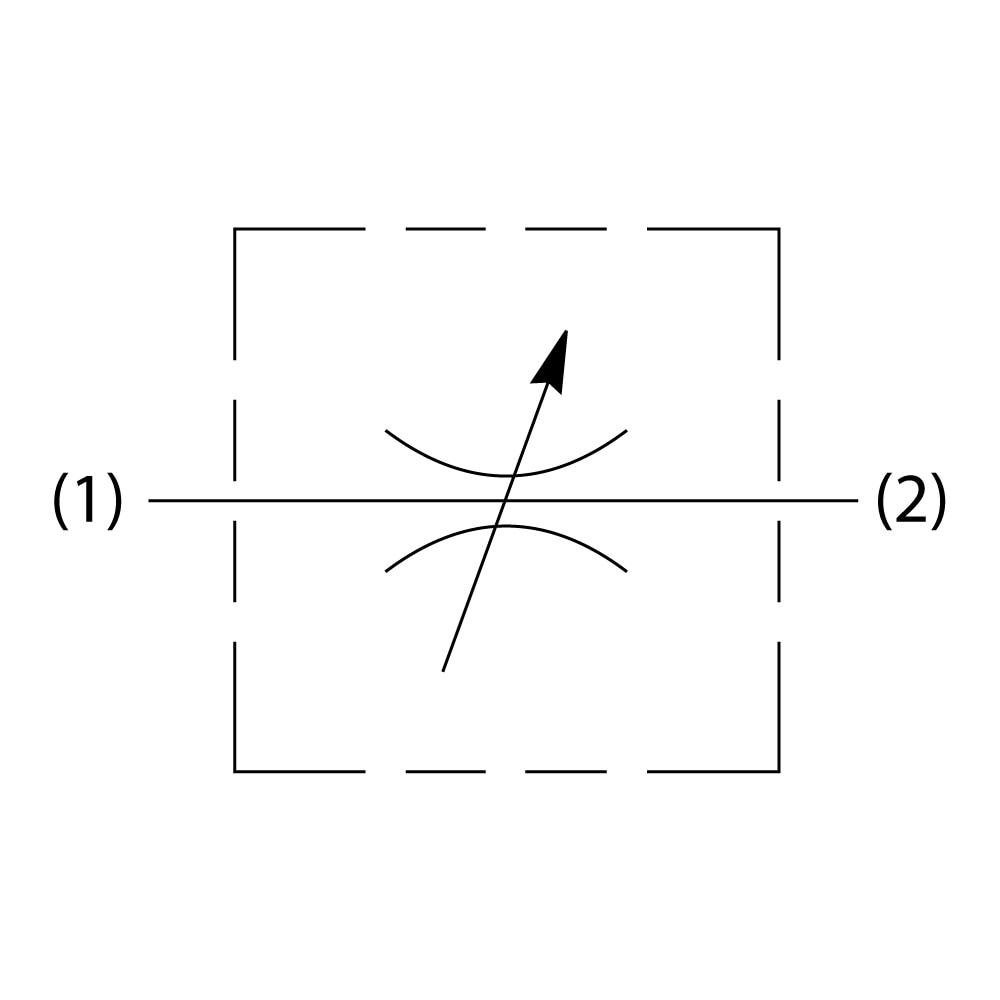

GLOBAL - Parker offers standard needle valves and needle valves with a reverse free-flow check. Parker’s needle valves are non-compensated adjustable orifices capable of flows up to 225 lpm (60 gpm) a...

Product Description

GLOBAL - Parker offers standard needle valves and needle valves with a reverse free-flow check. Parker’s needle valves are non-compensated adjustable orifices capable of flows up to 225 lpm (60 gpm) and pressures as high as 420 bar (6000 psi).

Parker’s family of needle valves feature a highly contamination tolerant design that allows for fine metering with manual adjustment to create and orifice and control flow. These valves can operate with hydraulic system flows as high as 225 lpm and pressures up to 420 bar with the option of an integrate reverse free-flow check valve. Parker’s needle valves or needle-check valves are ideal for cylinder or motor control and/or bleed-off applications within a broad range of markets, such as the agriculture, construction, material handling, industrial, oil & gas, and several more.

Markets:

• Agriculture

• Construction Equipment

• Material Handling Equipment

• Miscellaneous Industrial

• Miscellaneous Mobile

• Oil & Gas

Features/Benefits:

• High flow capacity from a small cavity

• Manual shutoff with extremely low leakage

• Fine adjustment control/sensitivity

• Very tolerant to contamination

• Tamperproof options available

• Free-flow reverse check available

• All external parts zinc plated

Applications:

• Accumulator bleed-off

• Motor speed control

• Cylinder speed control

Additional Technical Insight:

Needle valves offer economical solutions for applications that require basic adjustable control of hydraulic flow. The effective orifice size inside the valve is varied with screw or knob adjustments and the valve can be made tamper resistant with the addition of an optional cap. Shutoff can be achieved when the valve is adjusted completely closed. Once the adjustment is set, the valve acts as a fixed orifice. Like all fixed orifices, any changes in pressure will cause changes in flow. If constant flow is required regardless of system or load pressure, please consider Parker’s pressure compensated flow controls. Parker’s J02A2, NVH081, NVH101, and J06A2 cartridges are standard 2-port needle valves with fine adjustment options available. The orifice will meter in both directions, but flow from port 2 to 1 is preferred. If unrestricted reverse flow is required, an additional check valve will need to be used with these needle valve versions. Parker also offers J02B2, FV101, and FV102 needle valves with internal reverse free flow checks in order to reduce manifold size and component quantities.

Markets:

• Agriculture

• Construction Equipment

• Material Handling Equipment

• Miscellaneous Industrial

• Miscellaneous Mobile

• Oil & Gas

Features/Benefits:

• High flow capacity from a small cavity

• Manual shutoff with extremely low leakage

• Fine adjustment control/sensitivity

• Very tolerant to contamination

• Tamperproof options available

• Free-flow reverse check available

• All external parts zinc plated

Applications:

• Accumulator bleed-off

• Motor speed control

• Cylinder speed control

Additional Technical Insight:

Needle valves offer economical solutions for applications that require basic adjustable control of hydraulic flow. The effective orifice size inside the valve is varied with screw or knob adjustments and the valve can be made tamper resistant with the addition of an optional cap. Shutoff can be achieved when the valve is adjusted completely closed. Once the adjustment is set, the valve acts as a fixed orifice. Like all fixed orifices, any changes in pressure will cause changes in flow. If constant flow is required regardless of system or load pressure, please consider Parker’s pressure compensated flow controls. Parker’s J02A2, NVH081, NVH101, and J06A2 cartridges are standard 2-port needle valves with fine adjustment options available. The orifice will meter in both directions, but flow from port 2 to 1 is preferred. If unrestricted reverse flow is required, an additional check valve will need to be used with these needle valve versions. Parker also offers J02B2, FV101, and FV102 needle valves with internal reverse free flow checks in order to reduce manifold size and component quantities.

The Parker NVH101S Needle Flow Control Valves are high-performance flow control solutions designed for industrial applications. This needle valve offers a flow capacity of 225 lpm (60 gpm) and can withstand pressures of up to 420 bar (6000 psi). The NVH101S model features non-compensated adjustable orifices, providing precise flow control.

Made entirely of steel, these valves ensure durability and longevity, with the operational components crafted from hardened steel to withstand harsh industrial conditions. With a temperature range of -35 °F (-37 °C), this product is reliable across various climatic conditions. It is particularly ideal for sectors such as automotive, manufacturing, and energy, where effective flow control and management are crucial. With Parker's reputation for reliability and quality, the NVH101S enhances the efficiency of industrial systems, making it a valuable asset for any operation.

Technical Specifications

| Weight | 0.4 lb, 0.18 kg |

| Division | Hydraulic Valve Systems Division |

| Function | 2-Way |

| Flow Rate | 16 gal/min, 60 L/min |

| Leak Rate | 5 @ 5000 PSI (345 BAR) drops/min |

| Cavity Size | C10-2 |

| Needle Type | Coarse |

| Body Material | N/A |

| Configuration | Needle |

| Seal Material | D-Ring (Standard) |

| Actuation Type | Manual |

| For Fluid Type | Mineral-based or synthetic hydraulic fluids |

| Operation Type | Manually operated |

| Valve Material | All parts steel. All operating parts hardened steel |

| Connection Size | N/A |

| Connection Type | N/A |

| Maximum Flow Rate | 16 gal/min, 60 L/min |

| Installation Torque | 37 to 41 lb-ft, 50 to 56 Nm |

| Adjustment Mechanism | Screw |

| Operating Temperature | -35 to +200 °F, -37 to +93 °C |

| Filter Efficiency Rating | ISO 4406 18/16/13, SAE Class 4 |

| Maximum Operating Pressure | 5500 psi, 380 bar |

| Maximum Kinematic Viscosity | 45-2000 SSU (6 to 420 cSt) |

| Maximum Inlet Pressure Rating | 5500 psi, 380 bar |

| Maximum Operating Temperature | +200 °F, +93 °C |

| Minimum Operating Temperature | -35 °F, -37 °C |

| Brand | Parker |

| Model | Needle Flow Control Valves - NVH101S |

| SKU | NVH101S |

| Main Category | Parker |

Shipping & Returns Information

Shipping Information

- Shipped within 2-3 business days

- Free shipping over 500 TL

- Insured shipping

Return & Exchange

- 14 days return right

- Return in original packaging

- Fast processing guarantee